6.2: Cross-Section Behaviour {NEN 3650-2} [CHCKNEN]

Perform cross-section calculations and NEN-checks

General description:

Through this design function deformations and stresses are calculated in specified cross-sections of the pipeline. Cross-sections are located at the mid-sections of elements.

If the NEN 3650-2 norm option is selected in Design Function 1 (Project Definition) a dropdown-list becomes enabled which allows a selection between "Mohr", "Tresca", "Von Mises" and "Uniaxial". Stresses will be calculated according to the selected option. The unit stresses are the result of the calculated stresses divided by the applicable stress correction factor from NEN 3650-2 (see below) and the yield stress(es) of the pipe material defined in table ISTROP (Design Function 3.1). For detailed information see description of output data tables NENSMAX and NENSTRS.

Calculations according to Mohr, Tresca, Von Mises or Uniaxial are performed similar to Design Function 6.2, only the stress components are determined using standard weighing factors according to the NEN 3650-2 rules. Moreover maximum and detailed summated and principal stresses are provided in output tables TSTRMAX, TSTRESS, MSTRMAX and MSTRESS similar to Design Function 6.2 without application of any correction or weighing factor to make yield ellipse analysis possible.

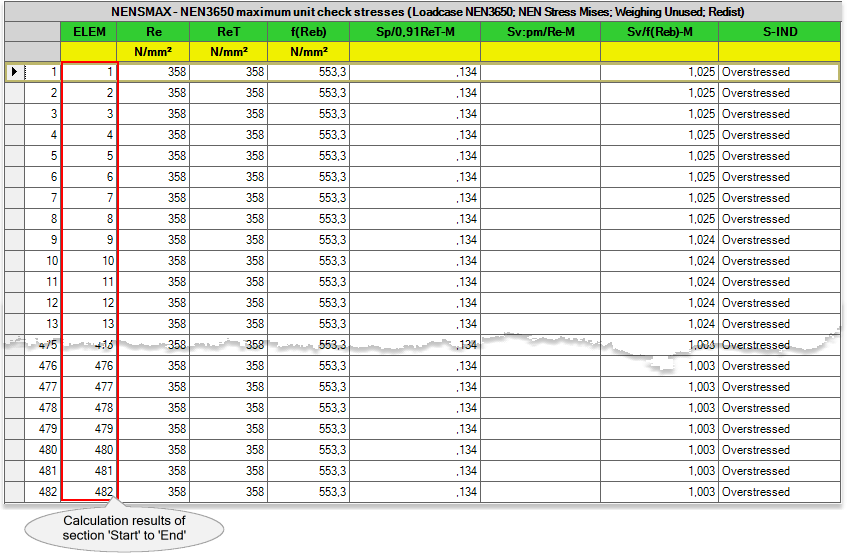

The function calculates the unit check stresses in specified cross-sections and abs(max/min) results are stored in the output data table NENSMAX. One dataline per cross-section specified. Detailed data over the circumference of the cross-section are contained in the output data table NENSTRS. This table only contains results of the last cross-section calculated. At the start of a new cross-section the NENSTRS table is cleared and during the calculations on the new cross-section filled with the detailed data of that new section.

The calculated radial deformations of the cross-section(s) are similarly collected in output tables RMAXNEN and RDPLNEN. Moreover maximum and detailed summated and principal stresses are provided in output tables TSTRMAX, TSTRESS, MSTRMAX and MSTRESS to make yield ellipse analysis possible.

If detailed data are required from each cross-section to be analysed, it is advised to perform this sub-function separately for each cross-section using the 'unlock'-functionality of this sub-function.

Overall results of previous calculations are accumulated in the output data tables of this sub-function until this function is set back. In that case all output data tables are cleared.

Explanation of the check stresses Sp, Sv:pm and Sv

|

Sp : |

the hoop check stress is calculated according to NEN 3650-2 Rules Stress correction factor is 1.1 (*) |

Sv:pm : |

the primary (membrane) stress due to primary loads. Only stress components with ..U.. identification are considered. The stress is reported if 1) there are only force-induced loads specified and 2) the pipeline does not follow soil settlements at (pile) supports below ground or the pipeline lies on supports above ground. Stress correction factor is 1.0 (*) |

|

Sv : |

the primary + secondary (membrane + wall bending) stress due to primary and secondary loads. All stress components are considered. The stress is always reported. Stress correction factor is 0.647 if ReT=Re (*) (In input table ISTROP). |

|

(*) ref: |

NEN 3650-2:2020 appendix D.3.1 (and) table D.4. |

Additional output data tables:

The additional output data tables are filled with detailed deformation and stress data concerning a mid-section of an element. Through these additional output data tables, detailed information on the behaviour of a cross-section can be obtained.

As the number of detailed data on a cross-section is quite substantial the detailed data per cross-section is not stored in the database. Results of calculations on a new cross-section overwrite the results of previous calculations. Hence, if a list of cross-sections has to be calculated, only the detailed data of the last cross-section will be available through the additional output data tables.

In case the designer wants to have available all detailed data per cross-section, the function can be performed with one cross-section at the time.

The unlock facility (refer to the overview panel help screen for more details) allows you to restart the calculation process from the last element calculation performed. This feature is especially useful when multiple cross-sections need to be analysed. When you use the unlock facility, the calculation results for the specified cross-sections in this table are added to the output data tables of this function.

After unlocking, the input tables in Design Function 6.2 can be modified. This means you can change the SECTION table to select which cross-section to calculate (next). This functionality enables you to perform a series of calculations on completely different parts of the pipeline.

If the SECTION table includes a cross-section that already has results stored in the output data tables, this cross-section will not be recalculated. However, the last cross-section specified in the SECTION table will always be calculated to obtain detailed stress results, unless it is the same as the last calculated cross-section.

When you use the unlock facility and subsequently perform a calculation for this Design Function:

•the results for the specified cross-sections in this table are added to the output data tables of this Design Function

•if the SECTION table includes a cross-section that already has results stored in the output data tables, this cross-section will not be recalculated. However, the last cross-section specified in the SECTION table will always be calculated to obtain detailed stress results, unless it is the same as the last calculated cross-section.

When setting back a locked design function, the result data in the output tables will be cleared and replaced by new calculation data. Unlocking, on the other hand, leaves previous calculation data in the output tables intact (does not clear it) and adds the new calculation data into the output tables.

![]() Unlock facility is available for specific functions only: Design Function 5 and Design Function 6.2.

Unlock facility is available for specific functions only: Design Function 5 and Design Function 6.2.

![]() Any design function following the unlocked function is set-back!

Any design function following the unlocked function is set-back!

How to's:

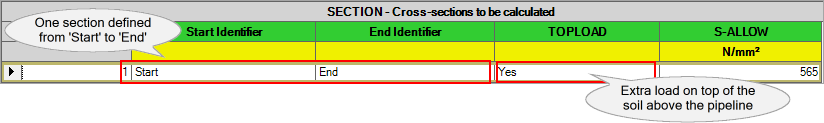

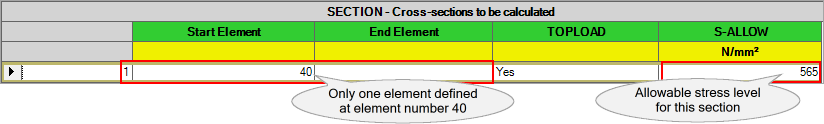

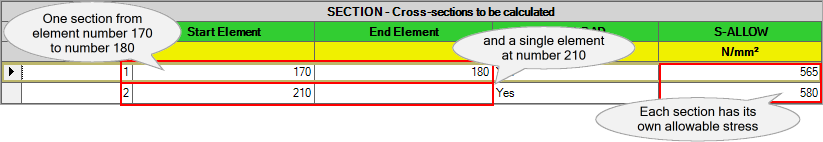

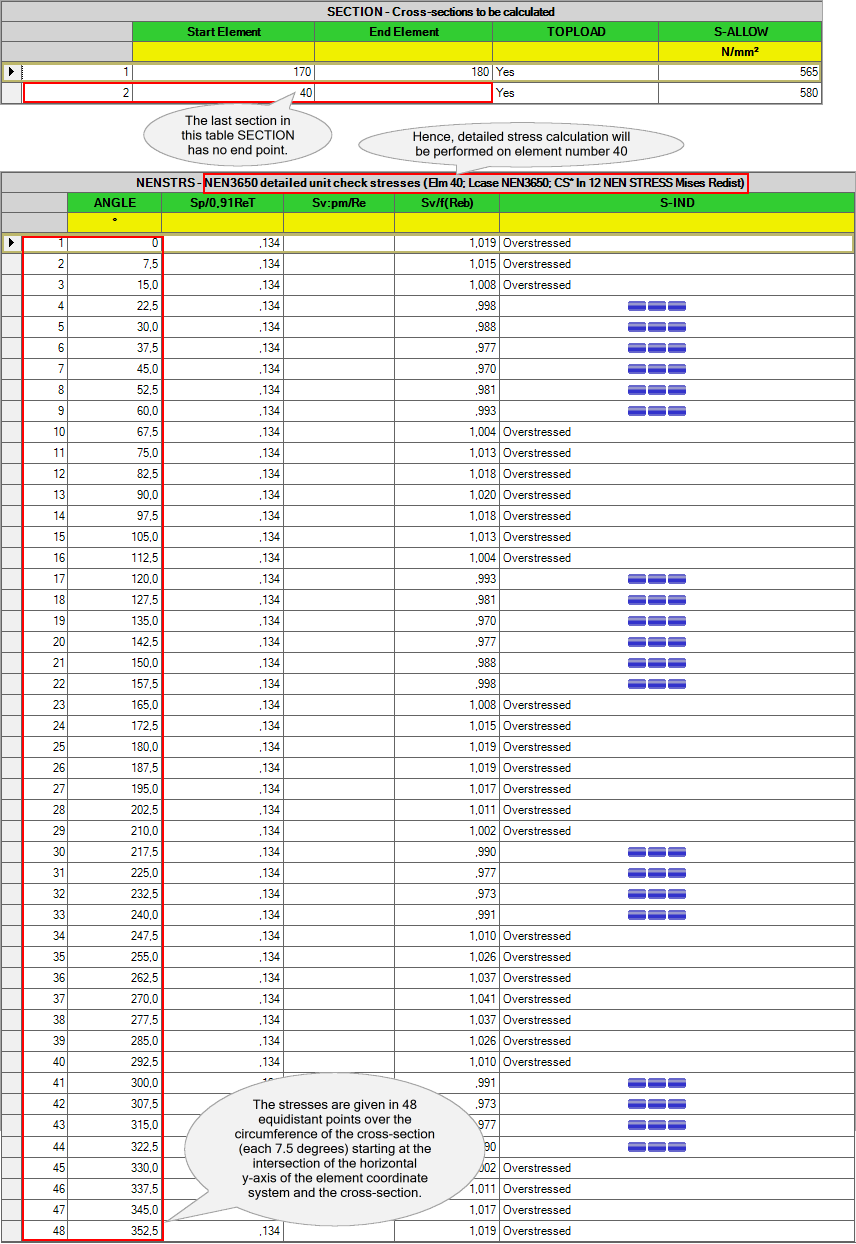

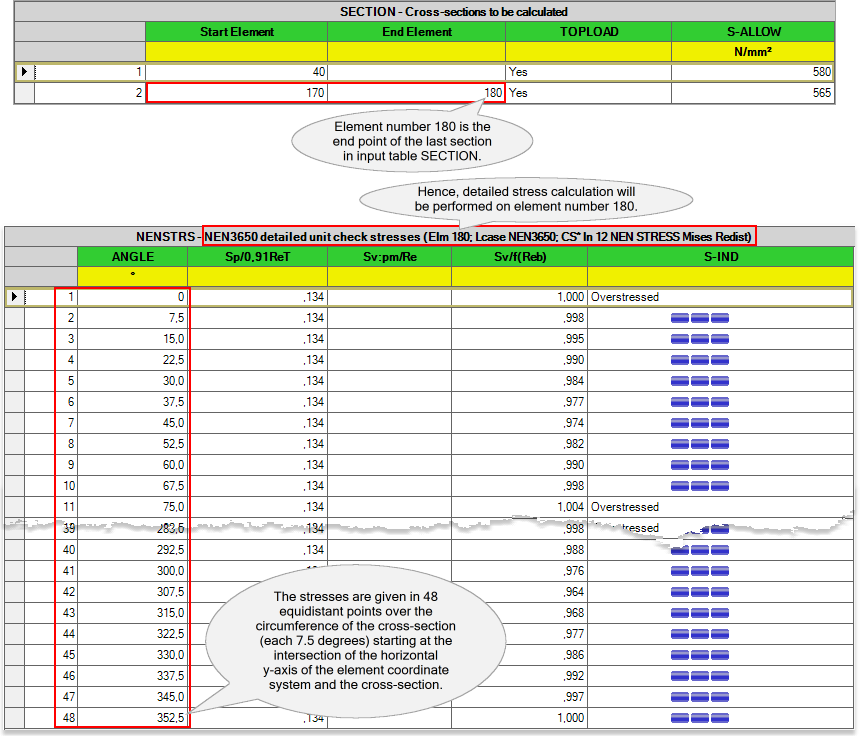

Using the input table SECTION, one or more sections can be specified by indicating the start and end points of each section. Examples of defined sections are shown below. Each section has additional loads on top of the soil and allowable stress value of 565 N/mm2.

Section with multiple elements Stress calculations will be performed on multiple elements within a defined range of the pipeline.  Section with one element only If no section is desired, it is sufficient to specify only the start point as the beginning of the section. The end of the section can be left blank. This also means that the stress calculation will only be done for the element at the given starting point.  Combination of sections Combination of both section with multiple elements and a single element is also possible.  |

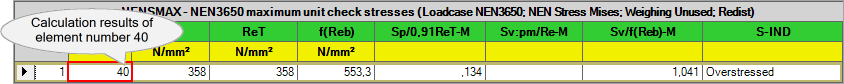

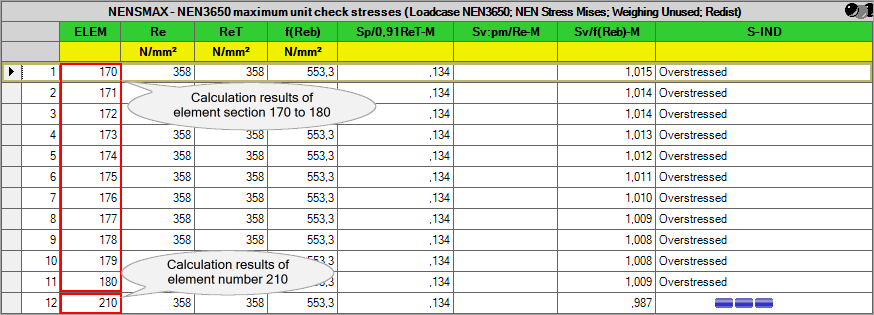

The results of the stress calculations contained in the output tables depend on the specified sections in this table SECTION. Only the calculation results for these sections are displayed in the output tables. Section with multiple elements  Section with one element only  Combination of sections

|

Detailed stress calculation results can be found in the additional output tables. The additional output tables contain various detailed stresses over the circumference of the cross-section where calculations have been performed. The stresses are given in 48 equidistant points over the circumference of the cross-section (each 7.5 degrees) starting at the intersection of the horizontal y-axis of the element coordinate system and the cross-section. Please note that the detailed calculation results shown in these tables are only of one specific cross-section (element). This specific cross-section of interest is automatically taken by Ple4Win if the cross-section is the last cross-section specified in this SECTION table. Or, in other words: •The cross-section is, in the absence of an end point, the start point of the last defined section in the SECTION table, or

•The cross-section is the end point of the last defined section in the SECTION table.

|

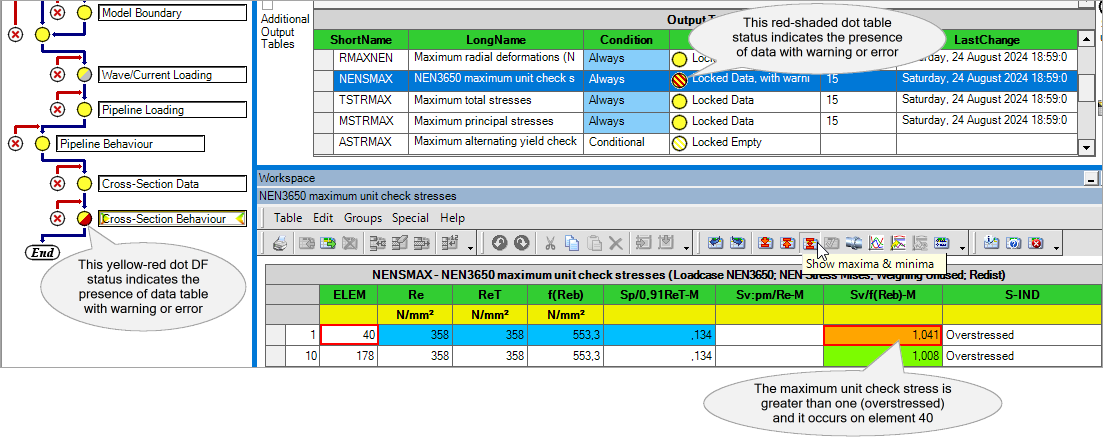

Sometimes, the data status of this Design Function may show a warning or an error. You can identify this by looking for a yellow dot with a red lower half in the Roadmap panel. If you see this half yellow-red dot, open the specific Design Function to check the data status of each table associated with this Design Function. For example, in this case, the output table NENSMAX has locked data with a warning, indicated by a red-shaded dot. This warning usually relates to the unit check stress having a value of one or greater. If this is the case, this warning will be displayed.

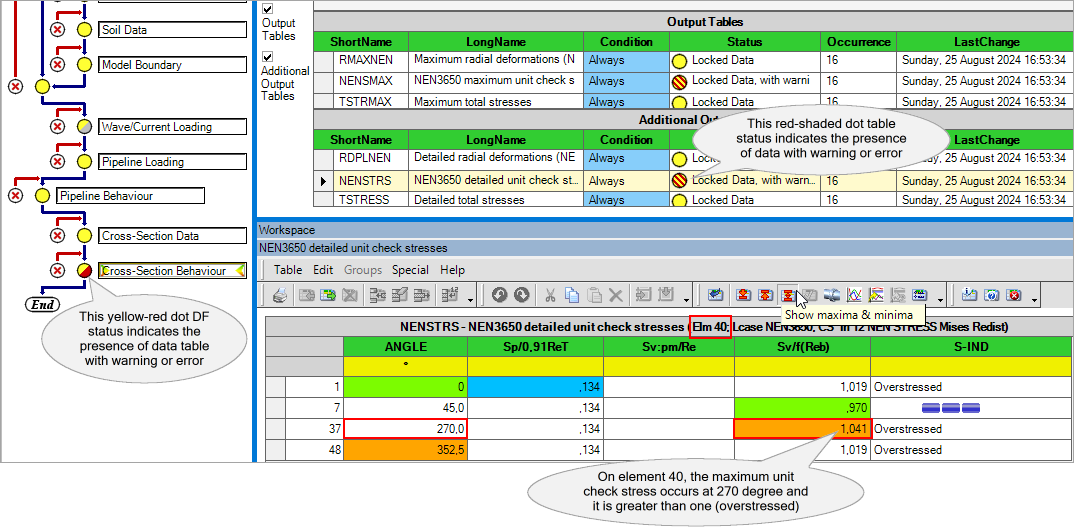

This also applies to the additional output tables. If any of the unit check stresses have a value of one or greater, a red-shaded warning status will be given. In the example above, the highest unit check stress is observed in element number 40. To gain a clearer understanding of the circumferential stress distribution across this element's cross-section, element number 40 has been designated as the cross-section of interest. The detailed calculation results are shown below.

|

H6303 (last modified: Sep 11, 2024)

See also: